Cutting Heads

All Purpose/Dirt Heads

MBH – All Purpose

- Light Rock

- Cobbles

- Dirt

- Clay mixes

- Maximum material flow

MBR – Flat Face Dirt

- Dirt or Clay

- Restricts material flow to reduce or prevent voids

- Chipper teeth with carbide tips available for hard soils with cobbles

MBRS – Open and Close Sand Head

- Running material or free flowing sands

- Cutting face can open and close to restrict material flow

Rock Cutting Heads

BMF – Single Row Flat Face

- Medium to hard rock

- Extra-large, heat treated, jacketed carbide teeth

BMF – Double Row Flat Face

- Medium to hard rock

- Extra-large, heat treated, jacketed carbide teeth

- Extra row of teeth for increased cutting surface action

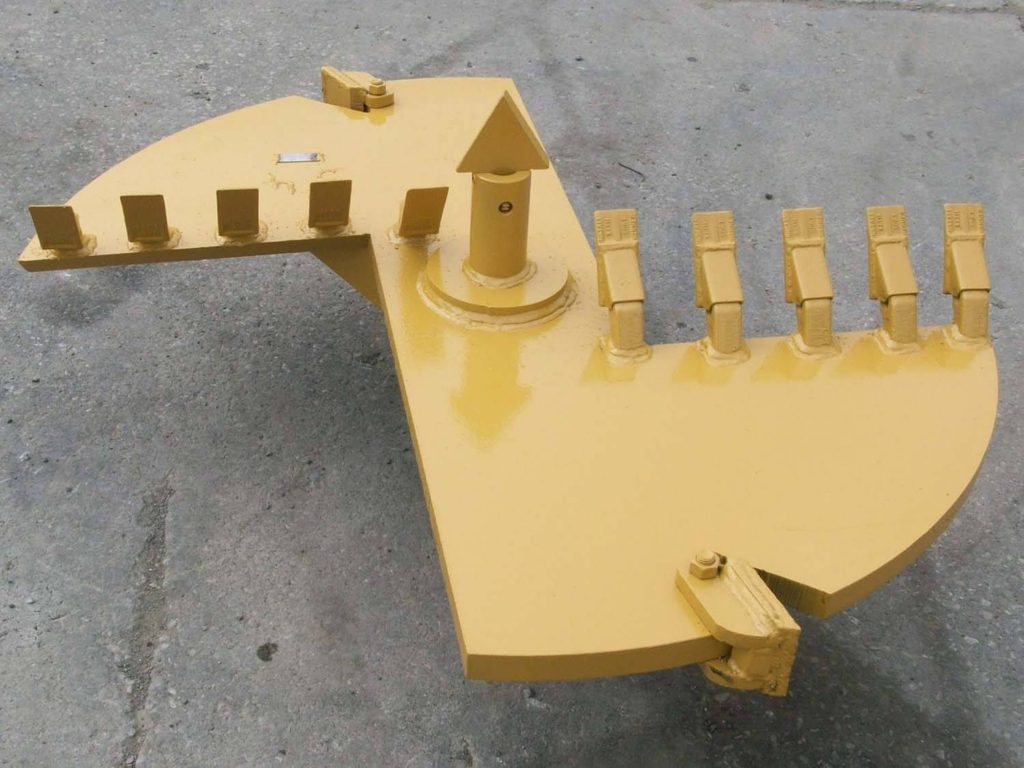

MBK – Hard Core X-Mas Tree

- Medium to hard rock

- Angular cutting plane

- Heavily gusseted frame

- Increased number of cutting teeth

Specialty Cutting Heads

SVH – Active Swivel Head

- “Needle” follows the pilot tube installed by a guided bore machine

- Bearing sealed in an oil bath allows the head to rotate while the needle and tube are stationary

- Multiple types of cutting heads can be used with one main swivel assembly

Custom

- Extreme Duty Cutting Head – 6” solid steel base with heat treated XL cutting teeth

- Customer going through a mixed face requested a heavy-duty base to handle the continuous hammer

- Other – Contact us to design a cutting head built for your job requirements

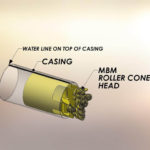

MRC – Roller Cone Cutting Head

- For use in hard to extremely hard rock

- Tungsten carbide insert rock bits

- Retractable Head Option – springs allow the cutting head to be pulled back through the casing

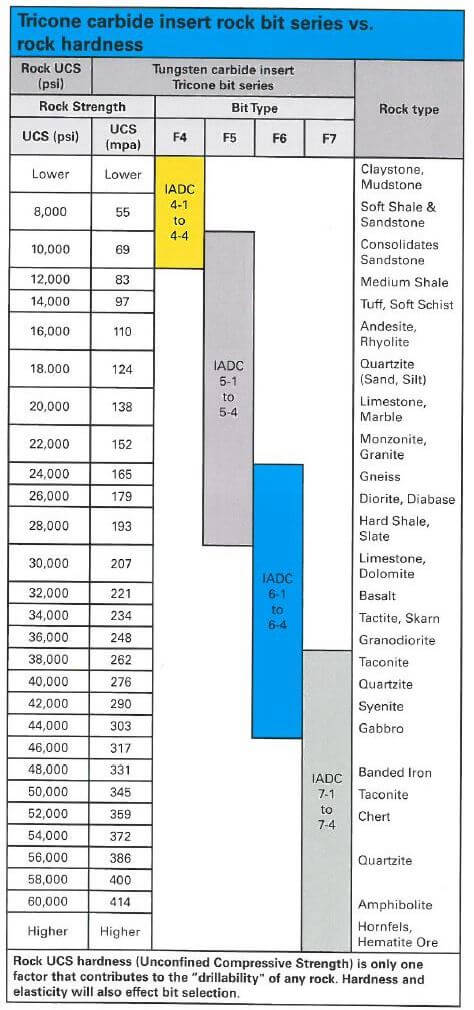

Roller Cone Bit Selection