Gear Boxes

Byrne Gear (formerly Crichton Manufacturing) has served the private and public sector with power transmission drives since 1990, our reducers are used everyday all over the world and beyond (see NASA project).

The engineering staff at Byrne Gear has consistently delivered the highest quality design for various projects. The projects listed below are a few examples of Byrne Gear’s design and manufacturing capabilities:

- NASA Moon Rover project, Byrne Gear designed and manufactured the final drives for the Moon Rover. The superior design and light weight of the Byrne unit was a major factor in being awarded this government contract.

- Nuclear Energy Agency, provided speed reducers to drive equipment to bury nuclear waste in salt mines in New Mexico. This project required special features due to the adverse environmental conditions of a salt mine.

- Boring, tunneling, and excavating equipment worldwide, Byrne Gearboxes provide the drive for sizes ranging from 12 inches to 14 feet. These applications typically see very heavy shock loads on the gearbox. The Byrne gearbox typically lasts 10 years or longer in these applications with little or no maintenance.

Gear Box Specs

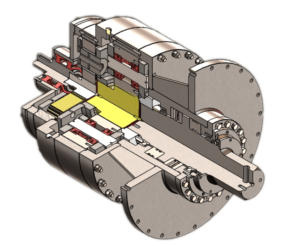

B19

Ratio

23.4 to 1

Max Torque Rating

6,000,000 In-Lbs

Weight

4486 lbs

Flange Mount

Dual Thrust bearing

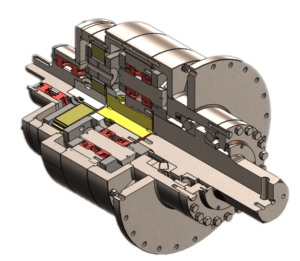

B16

Ratio

47.25 to 1

Max Torque Rating

3,000,000 In-Lbs

Weight

2675 lbs

Flange Mount

Dual Thrust bearing

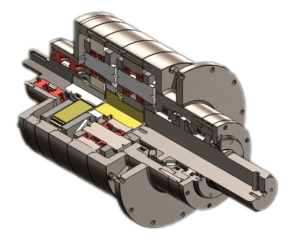

B13

Ratio

47.25 to 1

Max Torque Rating

1,000,000 In-Lbs

Weight

1840 lbs

Flange Mount

Dual Thrust bearing

Gear Cutting

Michael Byrne manufactures internal and external spur gears using gear hobs and shapers. Internal gears can be cut up to 34 inch diameters with a 6 inch face.

Gears are made up to AGMA 12 standard.